4. 7. 2024

We supplied key gas technology for the unique Energy Nest hybrid power source

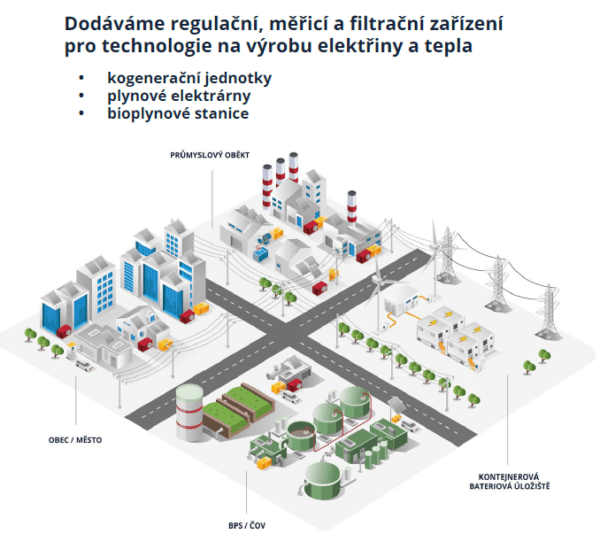

SIEMENS, as the general contractor, completed the construction of a modern energy source for E.nest Energy a.s., part of the Decci Group. The source is located near Vraňany in the Mělník region and includes six gas turbines with a total output of 32.4 MW and a battery storage with a capacity of 22 MWh. We joined the construction of one of the largest energy projects in the Czech Republic – from the design, manufacture and installation of the gas transfer station, gas control station and VTL industrial gas pipeline to the connection of the turbines.

A facility with one of the largest battery storage facilities in the Czech Republic has been built in Mělník. Together with gas turbines from CENTRAX, this resource can respond flexibly to the requirements of the transmission system operator CEPS and provide power balance services. The delivered technology has a virtually zero emission footprint in standby mode.

Our task within this project was to implement gas management for the turbines, which are fed with natural gas directly from the transit system. In cooperation with TECHKO, HUTIRA was the supplier of a gas transfer station, a gas control station with an output of 24,000 m3(N)/hour, an industrial gas pipeline and six filter skids with gas reheating for individual turbines. This contract is really special for HUTIRA because of its size and volume.

Due to the availability of gas pipelines in the vicinity, the station is connected to the transit system. “This means that it is necessary to ensure the regulation of the inlet pressure of 40 – 63 bar to the outlet pressure of 21 bar. Preheating of the gas in the control station was ensured by electric preheaters with an output of 240 kW,” explained Robert Sobočík, Technical Director of HUTIRA, who was responsible for the installation of the gas equipment in Vraňany.

“Before each turbine, a final filtration and reheating building is installed to ensure the required gas purity and temperature. To achieve the demanding gas purity requirements, we have placed a coalescing filter separator and an additional preheater,” Sobočík further said.

“The technology supplied has already been designed and delivered to enable a future switch to hydrogen to be used as a fuel for gas turbines and possibly to enable a connection and electrolyser that could be implemented at this site in the future”, stated Martin Panáč, SIEMENS Innovative Projects Manager and Chairman of the Board of AKU-BAT CZ.